I am blogging about Battleships...Again. It seems to be popular on my blog, For an Army guy I blog a lot about the big gray canoes that the Navy used to have in active service.

My Son back in 2012 on the U.S.S Alabama

You ever wonder where the name "Battleship" came from?, well I have the knowledge right here, I kinda wondered where the name came from, sure the name imparted the purpose of the ship. the name just conotated that the ship was there to kick butt and take names in the furtherance of National policies, The Big Stick of Diplomacy if diplomacy fails, you use the Big stick to beat the other guy into submission. And depending on the class of the ship and crew it can be spectacular.

Think ‘battleship’, and you

might think of the steam-driven steel warships that emerged during the

last decade or so of the nineteenth century, and which remained an

important measure of sea-force until the Second World War. In that, you

would be right.

The word ‘battleship’, though, is much older. The word ‘battle’

originated from Latin, via old French, and was used in old English as

early as 1297, spelt ‘batayle’.

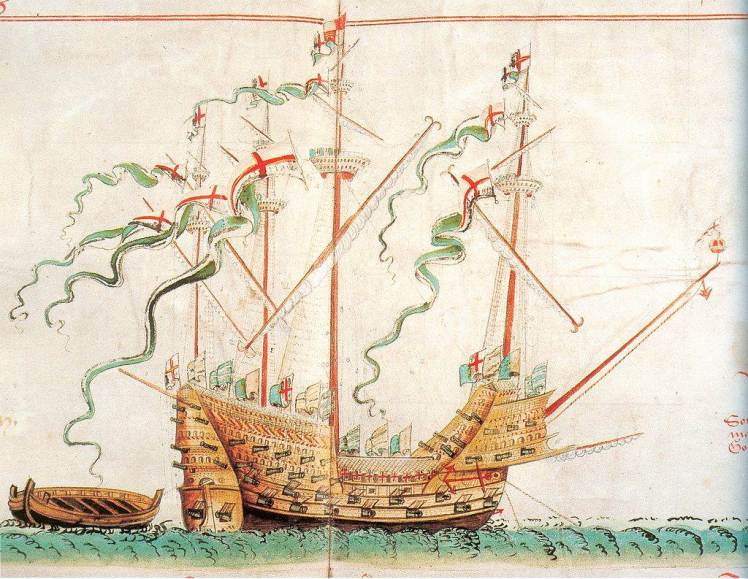

But it took a while to be applied to ships. By the early sixteenth

century, the term ‘great ship’ was in use to describe the most powerful

warship around, typically a one-off prestige vessel such as English

monarch Henry VIII’s Henry Grace a’ Dieu of 1514. Tactics had evolved by about 1600 into a system where fleets sailed into combat in lines. In the Royal Navy, the first four ‘rates’ – later three – could operate in that line of battle, and by the turn of the eighteenth century were generically known as ‘line-of-battle-ships’. The word ‘battleship’, an obvious contraction, was first used in 1794. Admiral Lord Nelson apparently used both forms in a sentence in 1804. ‘We may as well have a battle royal,’ he reputedly declared. ‘Line-of-battle-ships opposed to ships-of-the-line, and frigates to frigates’.

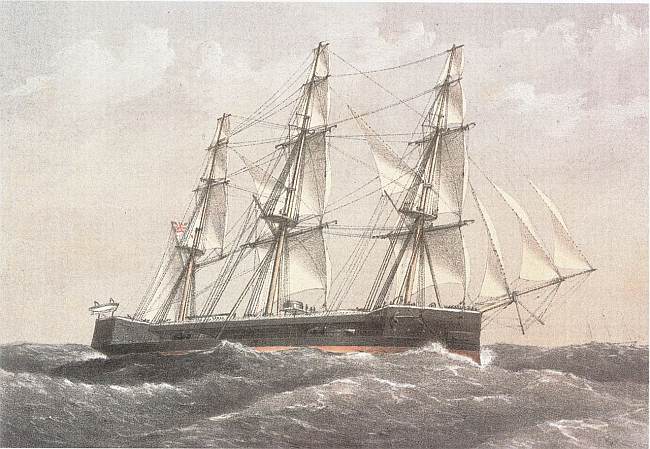

In this age of rapid technical change, however, terminology had trouble keeping up: the all-big-gun battleships that emerged in the first decade of the twentieth century became known as ‘dreadnoughts’ after the first British example, HMS Dreadnought. Larger types became ‘super-dreadnoughts’. Older battleships, in turn, became ‘pre-dreadnoughts’. It was temporary; the term ‘dreadnought’ fell out of use after the First World War, and such vessels again became ‘battleships’ and, on occasion, ‘fast battleships’.

MrGarabaldi,

ReplyDeleteI enjoyed this article very much. I have always found ships interesting. As a young boy of six in 1959 I received a 'Texaco Tanker' for Christmas. It was made to be played with as it had a working ballast tank, rudder, electric motor driving one shaft and the 'C' cells residing in the forcastle. It was modeled after a real tanker that had delivered oil, gasoline to Malta when it was under siege during WW-II. After my family moved back to Little Rock in 1962 I found another boy my age who had received one for Christmas too. We decided to 'convert' then to two masted sailing ships using kite sticks for our mast and old bed sheets for our sails. We sailed them in Broadmoor Lake which was and still is located behind Broadmoor shopping center which was located on University Ave which runs North / South. The lake is about a 40 acres and is contained on it's East side with an earthen dam. Had a lot of fun back then making our own stuff. All this in case you want to check it out on Google Earth.

I do have a question that I have been unable to find an answer for. That is how did the ship builders seal the steel plates that they riveted together to make the hull? The plates were overlapped and riveted together but surely they used some sort of material to seal them from the water. Modern hulls are welded so I can see how that would work for water tightness.

Thanks,

James Kidd

Hey James;

DeleteI am going to take a *swag* on your answer because I do sheetmetal on airplanes at work. If I recall, the pictures I saw of shipbuilding they used a tar or rubber based sealer that they would heat up that would bake and swell and seal the gaps between the steel and Iron. They would do the same thing with the Rivets, they would seal them the same way on the interior, the Iron being hot was malleable then would cool would cover most of the gap and what was left then would be sealed in tar or a rubber based layer as I understand the shipbuilding technique. Like I said, it is a SWAG.

Ah, the twists and turns of language to describe things... LOL Well done, sir!

ReplyDeleteHey Old NFO;

DeleteSometimes I try, LOL